In the highly competitive Philippine construction market, improving the utilization rate of individual equipment and controlling the comprehensive cost are the core concerns of every contractor. As a highly efficient and multi-functional attachment, the YG vibratory pile driver for excavator is helping local construction teams tap into the greater potential of existing excavators and generate better benefits in projects such as residential foundations and small-scale municipal works.【WhatsApp/WeChat/Phone】+86 13837122632

Hydraulic Pile Driver for Excavators Parameters

| Item | K150D | K250D | K350D | K400D | K450D |

| Eccentric Moment (kg·m) | 3.2 | 5.1/5.7 | 7.1 | 9.2 | 11 |

| Rotational Speed (rpm) | 2600 | 2600 | 2600 | 2600 | 2600 |

| Exciting Force (t) | 24 | 38/42 | 52 | 68 | 81 |

| Hydraulic System Working Pressure (bar) | 200 | 300 | 320 | 330 | 330 |

| Minimum Hydraulic Flow Requirement (Lpm) | 100 | 163 | 220 | 260 | 300 |

| Total Main Unit Weight (t) | 1.2 | 1.6 | 2.4 | 2.5 | 2.6 |

| Matching Excavator Tonnage (t) | 8-12 | 20-25 | 25-35 | 35-45 | 40-55 |

Customer Demand: Striking a Balance Between Budget and Efficiency

The customer is a company based in Pampanga province, specializing in the construction of local residential communities and small commercial facilities. They are advancing a project involving dozens of townhouses, and the pile foundation work faces several specific challenges:

- First, the soil quality on the construction site is uneven, with backfill soil on the surface and local clay layers in the lower part, requiring the piling equipment to have a certain degree of geological adaptability.

- Second, the project budget is limited, and they do not wish to invest in specialized large-scale equipment for a single construction process.

- Finally, they own multiple excavators of different tonnages and hope that the purchased attachment can be flexibly adapted to these machines, thereby improving the comprehensive utilization rate of existing equipment and the project turnover efficiency.

Solutions Provided by YG Vibratory Pile Driver for Excavator

Based on the customer’s medium-sized project scale and the equipment portfolio dominated by 20-ton class excavators, we recommended the K250D model excavator pile driver attachment. With its balanced performance and reliability, this product has targeted responses to the customer’s concerns.

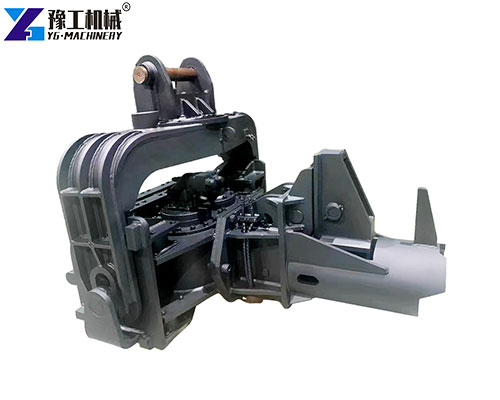

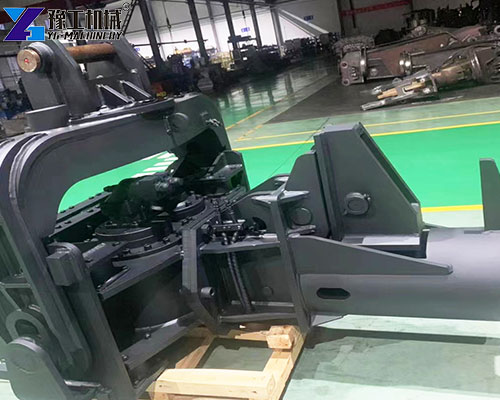

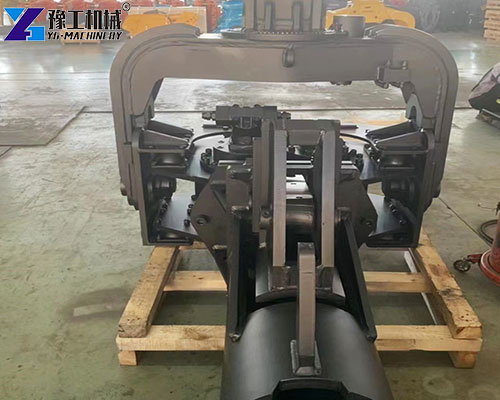

1. Vibratory pile driver for excavator: Suitable for Various Soil Types

This model uses high-frequency hydraulic vibration, with vertical excitation force from built-in double eccentric shafts to handle loose backfill to dense clay. Its “confluence output” function lets operators use standard mode for fast penetration in soft soil, and activate confluence for stronger force in hard soil—avoiding geological delays and keeping schedules on track.

2. Vibratory pile driver for excavator: Durable & Easy to Maintain

For long-term use, this hydraulic pile driver for excavators has a self-lubricating cooling gearbox and reinforced structure, coping with the Philippines’ hot climate and reducing overheating failures. Reinforced detachable booms (with extra oil passages), turning shafts, and built-in gears simplify daily maintenance and part replacement, cutting long-term costs and downtime.

3. Vibratory pile driver for excavator: Flexible & Quick to Convert

As a standard excavator pile driver attachment, it excels at quick connection. Via hydraulic quick-change connectors, the customer’s existing excavators switch from excavation to piling in minutes. This flexibility fits multi-building alternating construction, boosting single-excavator value and overall project scheduling agility.

Customer Feedback

The on-site project manager commented: “We chose the YG vibratory pile driver for excavator mainly because of its practicality and cost-effectiveness. In the villa foundation project, it handled the mixed soil layers very well, and the construction progress met expectations. Most importantly, it enabled our excavators to play more roles, eliminating the cost and coordination troubles of renting specialized piling equipment. The equipment operates stably, and daily maintenance is compatible with our own mechanical repair processes. This is a purchase that meets our actual needs.”

Contact Us

Choosing YG means more than just a piece of equipment—it’s a reliable, efficient solution that creates lasting value. Our excavator mounted pile driver and full product range solve your core challenges:

- Boost project competitiveness: Quickly turn your excavator into a high-efficiency piling platform, cutting costs and speeding up responses—ideal for space-limited or tight-schedule projects.

- Secure long-term benefits: Durable, easy-to-maintain design reduces downtime. “One machine, multiple uses” maximizes existing equipment value for better ROI.

- Comprehensive support: We offer timely technical advice, spare parts, and after-sales service to keep your equipment at peak performance.

If you need a practical, efficient piling solution in the Philippines, YG is ready to help. Contact us now for a personalized plan and quote tailored to your needs.【WhatsApp/WeChat/Phone】+86 13837122632