When constructing in sensitive areas adjacent to existing buildings, transportation pipelines or residential districts, safety and compliance are the top priorities. Traditional blasting and heavy-duty crushing methods are often restricted due to their uncontrollable risks. Excavator Drum Cutter provides a perfect alternative: its precision milling features with low vibration and low noise enable you to efficiently advance projects within the framework of strict safety and environmental regulations, completely resolving the dilemma of “being unable to start construction”.【WhatsApp/WeChat/Phone】+86 13837122632

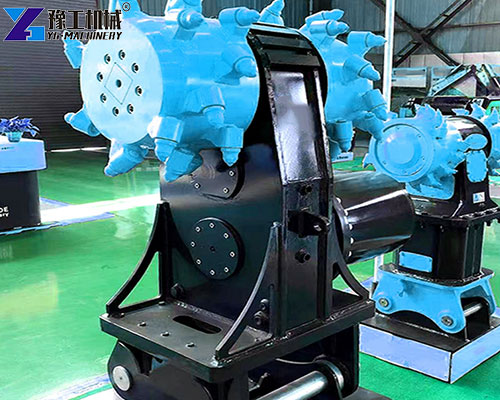

📐Horizontal Excavator Drum Cutter

The rotation axis of its milling head is perpendicular to the excavator arm, making it the first choice for large-area milling operations. It is specially designed for efficiently processing wide flat surfaces.

- 🔄Core Applications: Widely used in full-face tunnel excavation and finishing, smooth blasting in mine roadways, building demolition, asphalt or concrete pavement milling, as well as trench excavation, etc.

- 💪Performance Features: Equipped with imported high-torque hydraulic motors and high-strength spur gear transmission, it can output huge torque and easily handle hard rocks with compressive strength up to 90 MPa. The dense arrangement of high-strength alloy cutters on its wide milling drum ensures high material removal rate.

The following are the main model parameters :

| Product Model | Applicable Excavator (T) | Weight (kg) | Milling Width (mm) | Milling Head Diameter (mm) | Number of Cutters | Recommended Speed (r/min) | Recommended Flow (L/min) | Max Pressure (Mpa) | Max Torque (NM) |

| HX – X1 | 6 – 9 | 450 | 420 | 340 | 40 | 95 | 80 | 35 | 4700 |

| HX – X2 | 10 – 18 | 550 | 650 | 450 | 56 | 85 | 120 | 35 | 7000 |

| HX – Z1 | 20 – 27 | 1100 | 850 | 560 | 64 | 78 | 220 | 35 | 14300 |

| HX – Z2 | 30 – 40 | 1250 | 950 | 660 | 64 | 75 | 320 | 35 | 23300 |

| HX – D | 45 – 60 | 2450 | 1150 | 850 | 60 | 55 | 360 | 35 | 40300 |

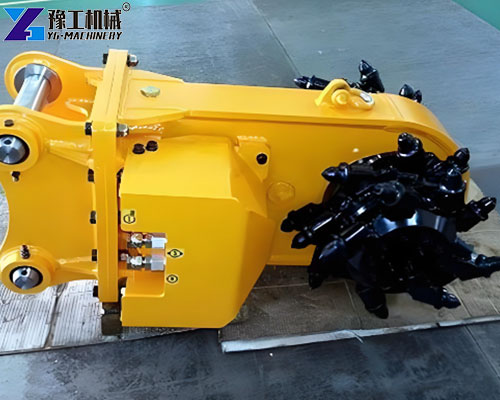

📏Vertical Excavator Drum Cutter

The rotation axis of its milling head is parallel to the direction of the excavator arm. This design gives it incomparable advantages in operations at specific depths.

- 🎯 Core Applications: Mainly used for precise excavation of narrow trenches, pile head demolition, profile finishing (such as slopes and bridge abutments), steel slag removal in steel plants, as well as material mixing operations.

- ⚙️ Performance Features: Also equipped with an imported hydraulic system to ensure stable power output. Its unique vertical structure is more convenient for penetrating and cleaning narrow spaces. Connecting sleeves of different lengths can be customized according to customer needs to adapt to different construction depth requirements.

The following are the key parameters:

| Product Model | Applicable Excavator (T) | Weight (kg) | Milling Head Diameter (mm) | Number of Cutters | Recommended Speed (r/min) | Recommended Flow (L/min) | Max Pressure (Mpa) | Max Torque (NM) |

| ZX – 1 | 6 – 9 | 340 | 400 | 28 | 80 | 75 | 35 | 3780 |

| ZX – 2 | 10 – 18 | 480 | 450 | 32 | 80 | 120 | 35 | 7900 |

| ZX – 3 | 20 – 27 | 900 | 550 | 44 | 75 | 200 | 35 | 12700 |

| ZX – 4 | 30 – 40 | 1100 | 580 | 48 | 65 | 260 | 35 | 19600 |

🆚 Core Comparison between Horizontal and Vertical Excavator Drum Cutter

Selecting the appropriate type of excavator drum cutter is the key to success.

🤔Choose Horizontal if your primary goals are:

- Efficient removal of large-area materials, such as tunnel excavation and mine working faces.

- Surface leveling or demolition, such as pavement milling and building demolition.

- Operations where width requirements are higher than depth requirements.

🤔Choose Vertical if your core needs are:

- Linear operations such as slotting and trenching.

- Processing vertical surfaces or complex profiles, such as pile head treatment and slope finishing.

- Narrow working spaces that require precise positioning and depth control.

Simply put, the horizontal drum cutter attachment for excavator is like a “razor”, good at handling flat surfaces; while the vertical drum cutter attachment for excavator is like a “carving knife”, good at processing profiles and trenches.

🌊 Excavator Milling Head Underwater Operation and Excellent Reliability

Both horizontal and vertical models of YG’s milling head for excavator adopt a special sealing design and have underwater operation capabilities. This allows it to be directly applied to marine engineering such as river dredging, reservoir finishing and port underwater foundation treatment without additional waterproof preparation, greatly expanding the application scope and time window of the equipment.

🔧 Excavator Milling Head Cutter Design and Maintenance Advantages:

The efficiency and service life of the milling head for excavator depend largely on the cutter system. YG equipment adopts a scientifically calculated and field-tested cutter installation sequence and layout to ensure that each alloy cutter head can exert maximum cutting efficiency. At the same time, the cutters adopt a modular design, which can be quickly replaced individually after wear, greatly reducing maintenance costs and downtime during long-term use, and ensuring that the equipment can continuously and stably operate under high loads.

In summary, YG Excavator Drum Cutter is not just an attachment, but a complete precision construction solution. By selecting the correct type (horizontal or vertical), you can unlock the full potential of the excavator in the field of hard material processing, and complete challenging tasks with lower comprehensive costs, higher safety and better project quality.

✅Contact Us

Choosing YG Machinery, you will get three core values:

- Precise Matching: According to your machine model and working conditions, we recommend the most suitable horizontal or vertical drum cutter attachment for excavator to ensure efficient construction.

- Reliable and Durable: The equipment adopts core imported components and scientific cutter layout to ensure stable operation in harsh working conditions and underwater environments, with simple maintenance.

- Long-term Return: One machine with multiple functions reduces equipment investment; precision milling improves material utilization rate; stable operation extends the service life of the main engine, achieving high investment cost performance.

If you have hard material processing needs for projects such as tunnels, mines and municipal works, this excavator milling head will be your ideal solution. Welcome to consult immediately to get a customized plan.【WhatsApp/WeChat/Phone】+86 13837122632