Equipment is not just a cost, but an asset that determines project profits and competitiveness. How to unlock the greater potential of your existing excavator fleet? The answer lies in professional empowerment. A high-performance Drum Cutter Attachment can upgrade an ordinary excavator into a versatile machine capable of tunnel finishing, mining excavation, and precision demolition. It is not only a tool for handling hard rock, but also a strategic investment for you to increase the output value per machine and expand high-value engineering business.【WhatsApp/WeChat/Phone】+86 13837122632

Typical Challenges Faced by Australian Customers 🎯

Our partner is an experienced mining service contractor in Western Australia. They are undertaking the tasks of precision slope finishing and safety platform excavation at a large open-pit iron ore mine in the Pilbara region, and have encountered the following problems:

- ⛰️Hard Rock Formations: The ore body and surrounding rock are mainly high-compressive-strength iron ore and basalt. Traditional hydraulic breakers are not only inefficient, but also highly prone to wear and tear.

- 📐High Construction Precision Requirements: To meet strict mine safety regulations, it is necessary to form smooth slope surfaces with precise angles. Traditional blasting or crushing methods are difficult to control, which may easily cause over-excavation or under-excavation.

- 🌿 Environmental and Community Pressures: The operation area is adjacent to sensitive ecological zones, and the high noise, heavy dust and severe vibration generated by traditional construction methods are increasingly restricted.

Solution: YG Drum Cutter Attachment✅

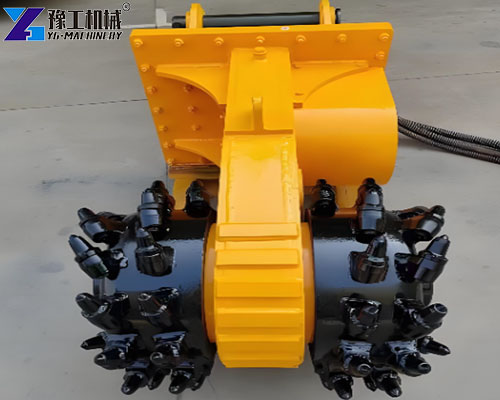

To address the customer’s challenges, YG provided the HX-Z2 model horizontal Drum Cutter Attachment adapted to their existing 40-ton excavators. This product is not a simple replacement tool, but a systematic solution.

The core product parameters are as follows:

| Product Model | Applicable Excavator (T) | Weight (kg) | Milling Width (mm) | Milling Head Diameter (mm) | Number of Cutters | Recommended Speed (r/min) | Recommended Flow (L/min) | Max Pressure (Mpa) | Max Torque (NM) |

| HX – X1 | 6 – 9 | 450 | 420 | 340 | 40 | 95 | 80 | 35 | 4700 |

| HX – X2 | 10 – 18 | 550 | 650 | 450 | 56 | 85 | 120 | 35 | 7000 |

| HX – Z1 | 20 – 27 | 1100 | 850 | 560 | 64 | 78 | 220 | 35 | 14300 |

| HX – Z2 | 30 – 40 | 1250 | 950 | 660 | 64 | 75 | 320 | 35 | 23300 |

| HX – D | 45 – 60 | 2450 | 1150 | 850 | 60 | 55 | 360 | 35 | 40300 |

YG Drum Cutter Attachment Overcomes Three Key Pain Points ✨

- ⚙️Rotary cutting conquers hard rock

As a high-efficiency Rotary Drum Cutter, the HX-Z2 features high-torque continuous cutting. With imported high-torque hydraulic motor and high-strength spur gear drive, it delivers up to 23,300 N·m torque, smoothly cutting hard rocks (compressive strength up to 90 MPa).

2. 🎯Millimeter-level precision achieved

This drum cutter attachment for excavator offers unparalleled control. Similar to a “CNC milling machine”, operators can precisely control milling depth, angle and contour—creating slopes that fully match design drawings, replacing uncontrollable traditional blasting.

3. 🤝Meets strict environmental & operational standards

Built for sustainable construction, it has low vibration and noise to reduce environmental interference. The Excavator Milling Head’s high reliability cuts failure and maintenance rates, while efficient operation lowers fuel consumption and overall costs.

Results of the Drum Cutter Attachment for Excavator

In this iron ore mine project, YG’s Drum Cutter Attachment demonstrated transformative capabilities. Customer feedback shows that under the same working conditions, the slope finishing efficiency has been increased by about 40% compared with traditional methods, and the one-time forming qualification rate is close to 100%. The project manager specifically pointed out: “It not only helped us complete the high-precision finishing task on schedule, but also won praise from the communities around the mining area because we significantly reduced noise and dust emissions.”

Why Choose YG Machinery?🏆

In the demanding Australian market, YG Machinery is your trustworthy partner for the following reasons:

- 💪Excellent and Reliable Product Performance

Our Drum Cutter Attachment adopts core imported components and high-strength design, specially built to cope with local high-hardness rock formations (with compressive strength up to 90 MPa) and complex working conditions such as underwater operations, ensuring strong power and long-lasting durability.

2. 🗺️Professional and Precise Services

We provide not only equipment, but also solutions. The YG team will accurately match the most suitable rotary drum cutter according to your specific project and existing excavator model, ensuring the equipment exerts its maximum efficiency.

3. 🤝Long-term Win-win Partnership

We are committed to helping you reduce long-term operation costs and enhance project competitiveness through our high-reliability excavator milling head products, becoming a solid backing for your market expansion.

Choose YG, choose reliable productivity. Welcome to contact us for customized solutions.【WhatsApp/WeChat/Phone】+86 13837122632