When a construction team in Ireland was faced with the intractable problem of “crossing sensitive areas” that could not be solved by traditional excavation methods, our company’s directional drilling rig provided the optimal solution. Recently, our company received the formal acceptance notice from the Irish customer, marking that the first batch of horizontal directional drilling equipment under the cooperation between the two parties has been fully in place.【WhatsApp/WeChat/Phone】+86 13837122632

HDD Drilling Machine for Sale Parameters

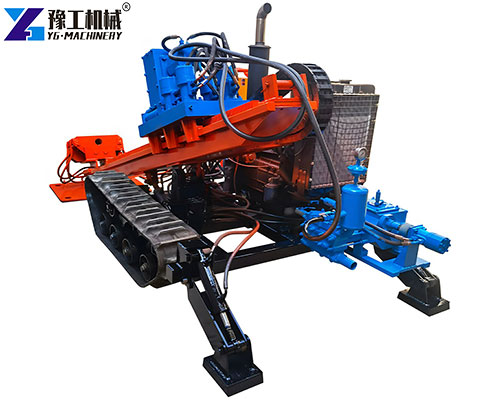

| Model | YG200 |

| Main engine part | 48kw 65HP |

| Host width | 1.6m |

| Host length | 3.8m |

| Host height | 1.8m |

| Travel system | remote control, crawler walking |

| Ground drive system | 2KM/hour |

| maximum working distance | 200 Meter |

| Drill pipe diameter | ≤500mm |

| Incidence angle | 10-22 degrees |

| Departure angle | 20 degrees |

| Host weight | 2.3t |

| Water injection system | three-cylinder mud pump |

| Pilot bit | bit diameter 100mm |

| Drill pipe length | 2 meters |

| Climbing ability | 35 degrees |

| Transfer case | 8tons |

Why Choose This HDD Drilling Machine for Sale

Integrating a number of innovative technologies, it ensures a stable and efficient construction process.

- Powerful Performance & Cost-effectiveness: Equipped with a 48kW engine, it features reliable power and low fuel consumption, greatly reducing operational costs and meeting the needs of long-term projects in Ireland.

- High-efficiency Transmission System: The push-pull rack-and-pinion structure improves transmission efficiency, extends service life by more than 30%, and reduces maintenance frequency.

- Flexible Angle Adjustment: The mast luffing mechanism supports a boring angle range of 13°-28°, adapting to the variable strata in Ireland and capable of handling everything from soft soil to hard rock.

- Intelligent Control Design: Wired remote control operation (optional) enhances safety, provides operators with a broad field of vision, and reduces the risk of accidents during loading and unloading by 50%.

- Dual-speed Adaptability: The dual-speed mode for rotation and push-pull can be switched in real time according to working conditions, increasing operation efficiency by 20%.

These features make the equipment an ideal directional boring rig, especially suitable for trenchless construction in densely populated urban areas of Ireland.

How the Directional Drilling Rig Conquers Sensitive Areas

The Irish customer purchased this directional drilling rig mainly for crossing rivers, highways and ecological reserves.

- Environmental Compatibility: With its compact size, the equipment can operate in confined spaces, avoiding damage to vegetation and soil in sensitive areas and complying with environmental regulations.

- Long-distance Precision Crossing: Boasting a maximum working distance of 200 meters, coupled with a high-quality mud pump, it ensures borehole stability and has successfully completed the laying of multiple underground pipelines.

- Rapid Relocation Capability: Adopting an engineering machinery chassis and rubber crawler design, it achieves a relocation speed of 2KM/h, accelerating the overall progress of projects.

- Adaptability to Complex Terrain: With a 35° climbing capacity, it easily navigates the hilly terrain in Ireland, expanding the application scope of the directional boring rig.

Customer feedback shows that this HDD drilling machine for sale has performed excellently in numerous “sensitive area crossing” tasks. Replacing traditional excavation methods has reduced project costs by approximately 40%.

Ensuring the Excellent Performance and Long Service Life of the Directional Drilling Rig

To ensure the long-term operation of the equipment in Ireland, we prioritize ease of operation and maintenance convenience.

- Remote Control System for Enhanced Safety: The remote control function reduces the risk of personnel working in close proximity, making it particularly suitable for construction in Ireland’s rainy weather conditions.

- Imported Hydraulic Components: Utilizing impact-resistant hydraulic valve blocks, it features minimal pressure loss and stable performance, lowering failure rates.

- Modular Maintenance Design: Key components such as the main pump and mud pump are easy to disassemble, enabling quick daily maintenance and minimizing downtime.

- Training Support: We provide on-site operation training to help the Irish team master the functions of the horizontal directional drilling rig and improve construction accuracy.

These measures make this directional drilling rig a reliable investment. Customers report that after the equipment was put into production, construction efficiency has increased by more than 35%.

Outstanding Performance of the YG200 Directional Drilling Rig in Ireland

The Irish construction team used the YG200 model to complete the laying of the first cross-border natural gas pipeline.

- Precision River Crossing: On the premise of avoiding water pollution, the rig’s angle adjustment function was utilized to successfully cross a 150-meter-wide river with a borehole deviation of less than 0.5%.

- Efficient Urban Construction: In downtown Dublin, the equipment’s compact size allows operation on narrow streets, minimizing traffic disruption and shortening the project cycle by 25%.

- Cost-benefit Analysis: Compared with traditional methods, trenchless construction saves costs on land compensation and restoration, reducing the overall investment payback period to 18 months.

The successful application of this equipment demonstrates the enormous potential of trenchless technology. In the future, we plan to promote more models to meet the diverse needs of more customers, from urban to rural areas.

Our equipment is built on solid parameters and driven by distinctive advantages, making us a trusted partner for Irish customers. Looking ahead, we will continue to optimize our products, contribute to global infrastructure development, and enable directional boring rigs to deliver value in more scenarios.【WhatsApp/WeChat/Phone】+86 13837122632