A mining enterprise in Mexico was plagued by high secondary crushing costs, as conventional equipment struggled to achieve precision cutting of high-hardness ores. After introducing our excavator rock saw, the enterprise realized efficient slicing of ores, which not only shortened the operation time but also significantly reduced equipment wear and tear.【WhatsApp/WeChat/Phone】+86 13837122632

Parameters

| Model | YG-CF1 | YG-CF2 | YG-CF3 | YG-CF4 |

| Suitable for excavators | 2~4T | 6~9T | 10~18T | 20~30T |

| Saw Disc Diameter | 0.4~0.8M | 1.2~1.6M | 1.8~2.2M | 2~2.8M |

| Cutting width | 5mm | 9mm | 14mm | 20mm |

| Cutting depth | ≤400mm | ≤800mm | ≤1100mm | ≤1400mm |

| Pressure | 30Mpa | 30Mpa | 30Mpa | 30Mpa |

| Flow | 30L/min | 80L/min | 120L/min | 190L/min |

Why YG Excavator Rock Saw Attachment Stands Out

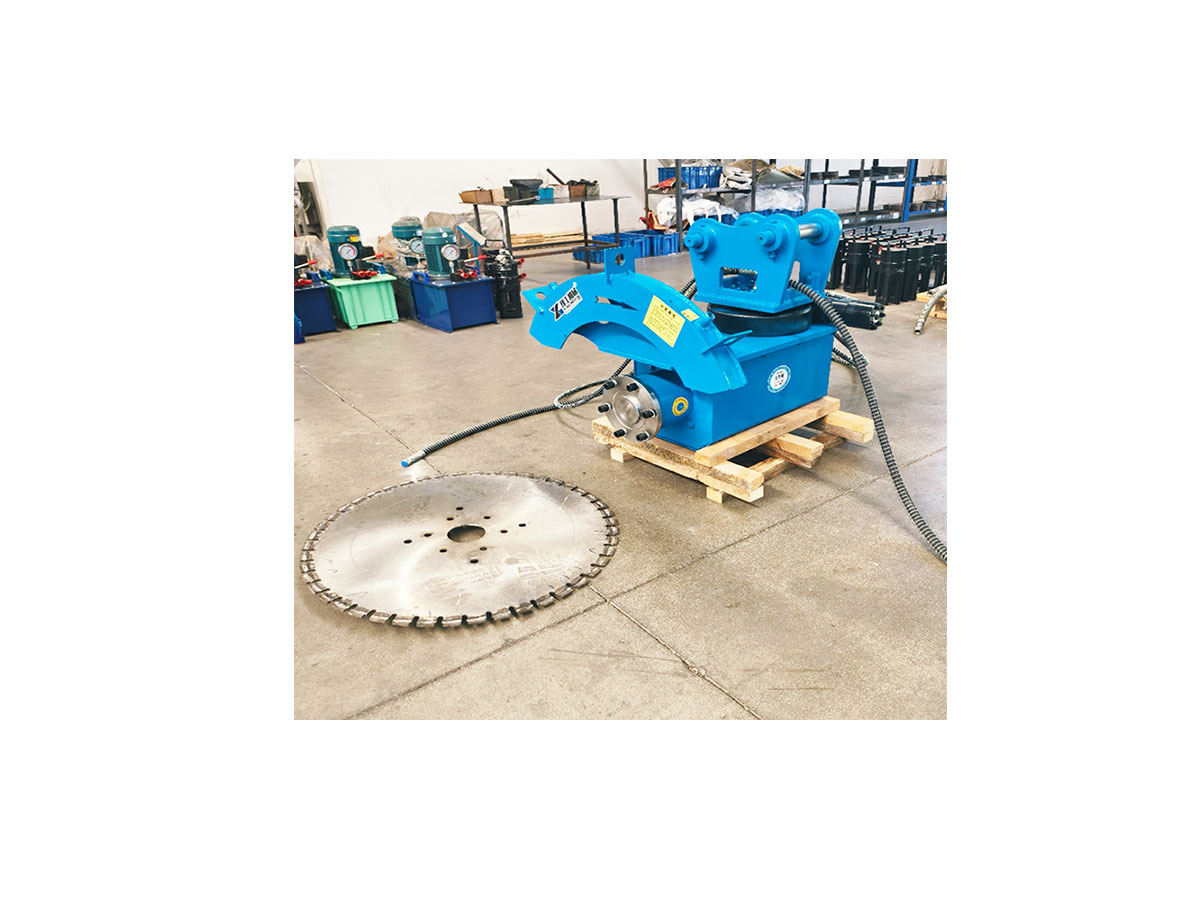

Based on the customer’s working conditions, we recommended the YG-CF3 model rock saw, which is compatible with their 20-ton excavator. This excavator rock saw for sale has won the customer’s trust with its unique design:

- Powerful and Reliable Core Power: Equipped with an imported high-performance hydraulic motor from Italy, it delivers stable output and strong torque, ensuring consistent power without attenuation during the cutting of high-hardness rocks.

- Intelligent System Protects Key Components: Integrated with a proprietary bidirectional protective hydraulic valve, it can effectively offset the hydraulic impact caused by huge inertia when the saw blade stops, fundamentally protecting the motor and hydraulic pipelines and extending the service life of core components.

- High-Strength Structure for Harsh Working Conditions: The saw blade base is made of special alloy steel with excellent elasticity and rigidity. It is not prone to deformation when subjected to enormous torsional stress, ensuring cutting straightness and making it suitable for long-term high-intensity mining operations.

Efficiency Improvements Brought by Excavator Rock Saw Attachment

Since its commissioning, this excavator rock saw attachment has created far more value than expected for the customer:

- Multi-fold Efficiency Improvement: Cutting has replaced inefficient crushing. Large ore blocks that originally required hours of hammering can now be smoothly sliced in just over ten minutes, making the overall secondary processing efficiency several times higher than that of traditional crushing methods.

- Significant Reduction in Comprehensive Costs: Firstly, the wear of the saw blade is much lower than that of the breaker chisel; secondly, the stable cutting motion greatly reduces the impact damage to the main excavator body, cutting down maintenance downtime and costs; finally, precision cutting improves the yield of high-quality materials, increasing revenue.

- High Operation Safety and Precision: Compared with the severe vibration and flying rock risks of breakers, cutting operations are more stable and controllable. The customer can accurately cut ores into the desired size, facilitating transportation and subsequent processing, and optimizing the production process.

Trust Extension

The successful application of the first rock saw attachment for excavator has laid a solid foundation of trust between our company and the customer. Later, based on their new needs for mine demolition and material separation, they purchased multiple sets of excavator attachments from us again, including “double-cylinder hydraulic shears” and “hydraulic quick couplers”. This indicates that our excavator rock saw for sale has not only solved a pain point but also opened up new ideas for the customer to carry out efficient and modern mining operations, thus fostering a long-term cooperative partnership.

Excavator Rock Saw Attachment Is Not Limited to Mining

The application of this high-performance rock saw machine attachment is far beyond mining:

- Municipal Engineering: Used for slotting hard rock pavements and silent demolition of concrete foundations or retaining walls.

- Tunnel and Subway Construction: Handling hard rock formations encountered during tunneling and trimming profiles.

- Post-disaster Rescue: Quickly cutting and clearing large concrete and rock components after earthquakes and collapses.

- Stone Mining: Assisting in the initial block segmentation of stones such as marble and granite.

The professional excavator rock saw attachment replaces “disordered crushing” with “precision cutting”, achieving an all-round leap in efficiency, cost, safety and material output quality. If you are also looking for a better solution to the decomposition of high-hardness rocks or concrete, this efficient rock saw attachment for excavator is undoubtedly an investment worthy of your in-depth understanding. The YG team is always ready to provide you with professional working condition evaluation and product selection suggestions, helping your projects reduce costs and increase efficiency.【WhatsApp/WeChat/Phone】+86 13837122632