How to conduct efficient and low-impact pile foundation construction in dense urban areas is a practical challenge faced by many engineering teams. With its quiet, efficient and highly adaptable features, the YG hydraulic pile breaker has been successfully applied to key projects in Singapore, providing an innovative solution to this dilemma.【WhatsApp/WeChat/Phone】+86 13837122632

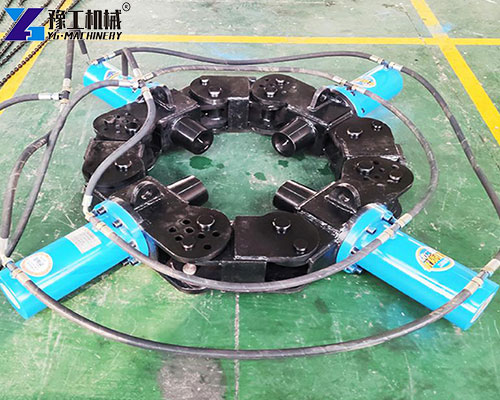

Pile Head Breaker Parameters

| Module Number | PCS | 4 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| Combination of the total weight | KG | 1600 | 2640 | 2970 | 3300 | 3630 | 3960 | 4290 | 4620 | 4950 | 5280 | 5610 | 5940 |

| Pile diameter range | mm | 400-600 | 600-800 | 800-1000 | 1000-1150 | 1150-1300 | 1300-1500 | 1500-1650 | 1650-1800 | 1800-1970 | 1970-2200 | 2200-2360 | 2360-2500 |

| Hydraulic excavator | T | 20T-30T | 30T-40T | Hydraulic system/pump station | |||||||||

| Max.Thrust | 300KN | Max.Cylinder required | 20L/min | Machinery Tonnage | ≥20T | Location pinΦ35 | |||||||

| Max.Cylinder Trip | 300mm | Chisel diameter | 110mm | Single module weight | 335KG | ||||||||

| Max.Cylinder Pressure | 300MPa | Max.Hoist Capacity | ≤500mm | Single module size | 1015*865*340mm | ||||||||

Project Background and Customer’s Core Needs

This Singapore project is located in a mature urban area, and the customer faced several specific challenges during the pile foundation processing phase:

- Strict environmental protection restrictions: The construction site is adjacent to commercial and residential areas. Local regulations have extremely strict control standards for construction noise, dust and vibration. Traditional pile breaking methods such as blasting or violent impact are completely unfeasible.

- Tight construction schedule pressure: The overall progress of the project is tight, and a large number of pile heads with different diameters need to be processed during the pile foundation phase. The customer is in urgent need of a pile head breaking machine solution that can significantly improve efficiency and shorten the construction period.

- Complex on-site conditions: The construction site has limited space and extremely high requirements for construction safety. The equipment needs to have good adaptability and controllability.

How YG Pile Breaker Accurately Meets Customer Needs

In response to the above challenges, the YG hydraulic pile breaker provides a comprehensive solution:

- Compliance with environmental protection regulations: The equipment adopts full hydraulic static pressure drive, which only generates extremely low noise and negligible vibration during construction, and no dust is produced. It perfectly meets the strict environmental protection construction regulations in Singapore’s urban areas and ensures the smooth progress of the project in sensitive areas.

- Improved construction efficiency: Its modular design is the key to high efficiency. By quickly combining 9 to 12 standard modules, this pile breaker machine can flexibly adapt to the main pile diameter range in the project without frequent replacement of large-scale equipment. The processing time per pile is reduced by more than 80% compared with manual methods, effectively ensuring the construction period.

- Enhanced construction controllability and safety: The equipment adopts a static pressure radial force application method, with uniform and controllable force output, providing a stable operation foundation for operators. At the same time, the entire pile breaking process can be completed remotely by the excavator operator, realizing the separation of man and machine, effectively ensuring personnel safety and adapting to complex on-site terrain.

Performance of Pile Breaker in Actual Projects

At the construction site, the YG equipment demonstrated excellent reliability and convenience:

- Rapid deployment and adaptation: The equipment modules are connected by pins, and assembly can be completed quickly on site. According to different pile diameters, operators can flexibly adjust the number of modules to achieve “one machine for multiple purposes”, which greatly improves equipment utilization and transition efficiency.

- Stable and efficient operation process: After connecting with a 35-ton excavator on site, this pile head breaker started efficient operation. Its conical top design effectively prevents the drill rod jamming problem caused by soil accumulation, ensuring continuous and stable operation even in humid environments.

- Convenient operation experience: The clear hydraulic control system makes it easy to master the equipment’s start-stop and pressure adjustment, lowering the operation threshold. Combined with the mobility of the excavator, the pile head breaking process becomes smooth and efficient.

Feedback from Singaporean Customers

After the project was completed, the customer highly recognized the comprehensive performance of the YG equipment, with the main feedback focusing on the following points:

- Recognition of environmental compliance: The customer specifically pointed out that the low-noise feature of this pile breaker machine is the key to their continuous construction within the specified time. No complaints were received from the surrounding community, which was difficult to achieve in previous urban projects.

- Satisfaction with efficiency and reliability: The customer believes that the equipment has a high attendance rate and low failure rate, and its stable performance provides a strong guarantee for catching up with the construction period. This pile head breaker fully meets the efficiency expectations at the initial stage of the project.

- Intention for future cooperation: Based on this successful cooperation experience, the customer stated that they will give priority to adopting YG’s pile breaker solution again in similar urban engineering projects in the future.

Contact Us

YG Machinery has always focused on providing professional pile breaking solutions for global customers. We are well aware of the unique challenges faced by different markets and different projects.

If you are looking for reliable, efficient pile breaking equipment that can cope with complex environments for your project, please feel free to contact YG Machinery at any time. Our professional team will provide the most targeted equipment selection suggestions and technical support according to your specific working conditions.【WhatsApp/WeChat/Phone】+86 13837122632